Introduction

If you're in the food packaging, pharmaceutical, label, or adhesive tape industry, chances are you’ve heard of glassine paper. With its smooth surface and semi-transparent look, it’s often mistaken for plastic—but it’s actually a natural fiber-based paper that’s both eco-friendly and highly functional. In this article, you’ll learn everything you need to know about glassine paper: what it is, how it’s made, its key features, and its wide range of uses.

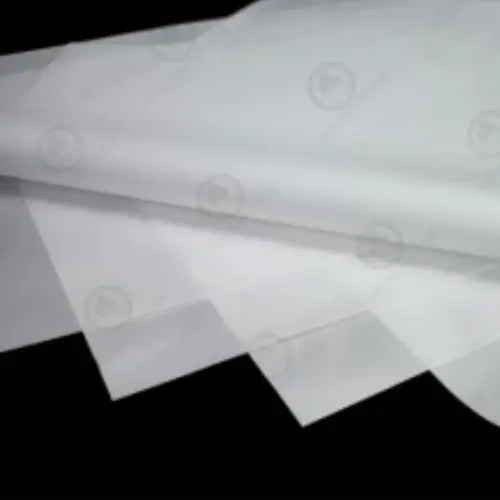

What Is Glassine Paper?

Glassine paper is a smooth, semi-transparent specialty paper with a glossy finish. It’s made from high-density, filler-free virgin wood pulp. During manufacturing, it’s treated with PVA (polyvinyl alcohol) and then supercalendered under high pressure and heat. This gives glassine its unique touch—soft, silky, and resistant to grease, moisture, and scratching. These qualities make it ideal for high-performance packaging across industries.

How Is Glassine Paper Made?

Base Paper Quality Control

The quality of the base paper is crucial. To ensure performance, the paper must be made without any fillers and have good bulk, consistent surface sizing, and minimal cross-directional shrinkage. These attributes help maintain stability in the later production stages.

Moisturizing Stage

Moisturizing is a critical step in making glassine paper. The paper is rehydrated, raising moisture content from 5–6% to about 20–21%, which improves flexibility and smoothness. Heated water (30°C–90°C) is used to ensure even absorption.

During this stage, a surface sizing solution is applied using a mix of polyvinyl alcohol and specialized adhesives, along with fluorine-based additives to improve oil and water resistance. Glue concentration is kept low (0.4%–0.6%) to prevent sheets from sticking. The paper rolls are then sealed and stored for 24 hours to stabilize their internal structure.

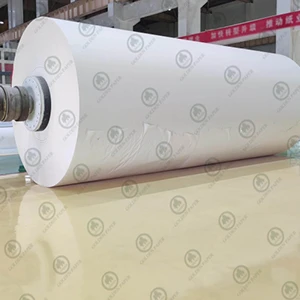

Supercalendering

To achieve glassine’s signature transparency and gloss, supercalendering is essential. Heated calender rolls (up to 300°C) compress the paper to increase its smoothness and density.

Gloss rolls are used to enhance the surface finish, and imported rolls are alternated to avoid scratches. Different paper weights require adjusted pressure and speed settings to maintain consistent quality.

Rewinding and Cooling

After calendering, the paper retains high internal heat (up to 70°C in summer). To prevent warping or curling, cooling rollers are used before the final rewinding and packaging stage, ensuring the paper remains flat and visually appealing.

The Benefits of Glassine Paper

High Strength

Glassine paper is made from a high percentage of long-fiber virgin pulp, pressed under high pressure for a dense, stable structure. This gives it excellent tensile and compression strength—it doesn’t tear easily, even under mechanical stress.

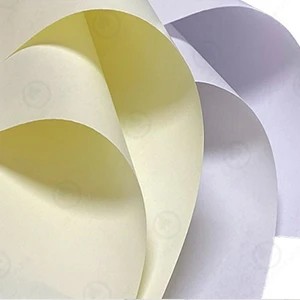

Exceptional Transparency

Thanks to its tightly packed fibers and minimal air gaps, light passes through glassine evenly, giving it a natural semi-transparent appearance. This is especially useful for showcasing product details in packaging.

Grease and Moisture Resistance

Glassine paper’s dense, smooth surface naturally resists oil and water without the need for extra coatings. That’s why it’s a popular eco-friendly choice in food and pharma packaging.

Smooth Surface Finish

After high-temperature polishing, glassine paper achieves ultra-smoothness and low surface friction, making it perfect for precision printing, laminating, and labeling processes.

Eco-Friendly Material

Made from 100% natural wood pulp, glassine is acid-free, pH-neutral, and contains no fluorescent agents. It’s recyclable, compostable, and biodegradable—ideal for sustainable packaging.

Food and Beverage Packaging

Glassine paper is widely used in disposable food packaging: baking paper, sandwich wraps, candy wrappers, and cheese sheets. Its grease- and moisture-resistant qualities help keep food clean and fresh. Free from fluorescent agents and toxins, it meets food-grade safety standards and is suitable for high-heat or refrigerated storage.

Pharmaceutical Packaging

Glassine is perfect for medical-grade packaging like capsule envelopes and patch backings. Its barrier properties protect medications from moisture and contaminants. The clean, smooth surface ensures it meets hygiene standards. Some versions are also heat-sealable for compatibility with aluminum or plastic composites.

Labels and Adhesive Tapes

Glassine is a top choice for release liners in pressure-sensitive labels and double-sided tapes. Its smooth, dense surface supports even adhesive application and clean peel-off without tearing. This is crucial for high-speed automatic labeling lines.

Industrial and Electronics Applications

In electronics and manufacturing, glassine paper is used as protective layers, anti-static barriers, or cushioning sheets. Its clean surface and optional anti-static treatment help protect sensitive components from dust and friction. It also handles cutting, molding, and bonding well in industrial settings.

Conclusion

If you're looking for a packaging material that combines functionality with sustainability, glassine paper is a top choice. At Golden Paper, we specialize in high-quality paper solutions for a wide range of industries. Contact us today to get glassine paper specifications and a quote tailored to your needs. Visit our blog for expert advice, product insights, and tips on choosing the right packaging paper to boost your brand’s performance and sustainability goals.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id